Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

Ici, vous pouvez décrire un morceau de texte que vous souhaitez exprimer

Navigating the World of Wholesale Hydraulic Hose Fittings: Your Ultimate Guide

In the realm of hydraulic systems, the role of hydraulic hose fittings is pivotal. These small but mighty components are the linchpins that hold together the intricate web of hoses and machinery, ensuring the smooth operation of countless industrial and mobile applications. This guide is dedicated to unraveling the complexities of wholesale hydraulic hose fittings, providing insights into their types, applications, and the nuances of selecting the perfect fit for your hydraulic needs. We’ll also highlight the importance of quality sourcing, with a nod to the esteemed manufacturers of China air brake hose fittings and the accolades of the China best swaged hose fitting factory.

Understanding Hydraulic Hose Fittings:

Hydraulic hose fittings are the connectors at the heart of any hydraulic system, tasked with the critical job of forming secure, leak-proof connections. These fittings are as varied as the applications they serve, crafted from different materials and designed to withstand a range of pressures and environmental conditions. The integrity of a hydraulic system hinges on the reliability of these fittings, making their selection and installation a matter of utmost importance.

Types of Hydraulic Hose Fittings:

The market offers a plethora of hydraulic hose fittings, each tailored for specific scenarios and demands. Let’s explore some of the most prevalent types:

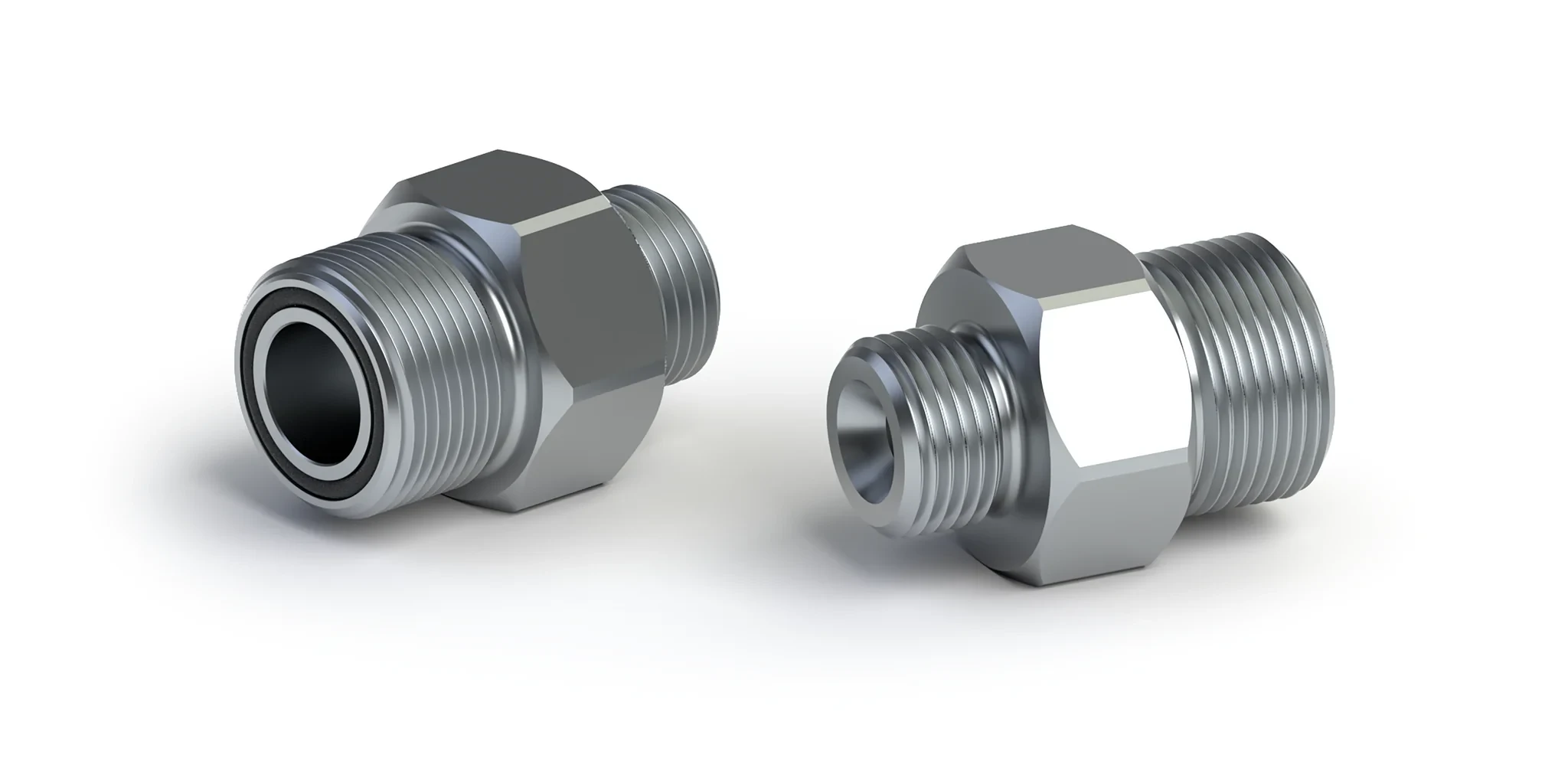

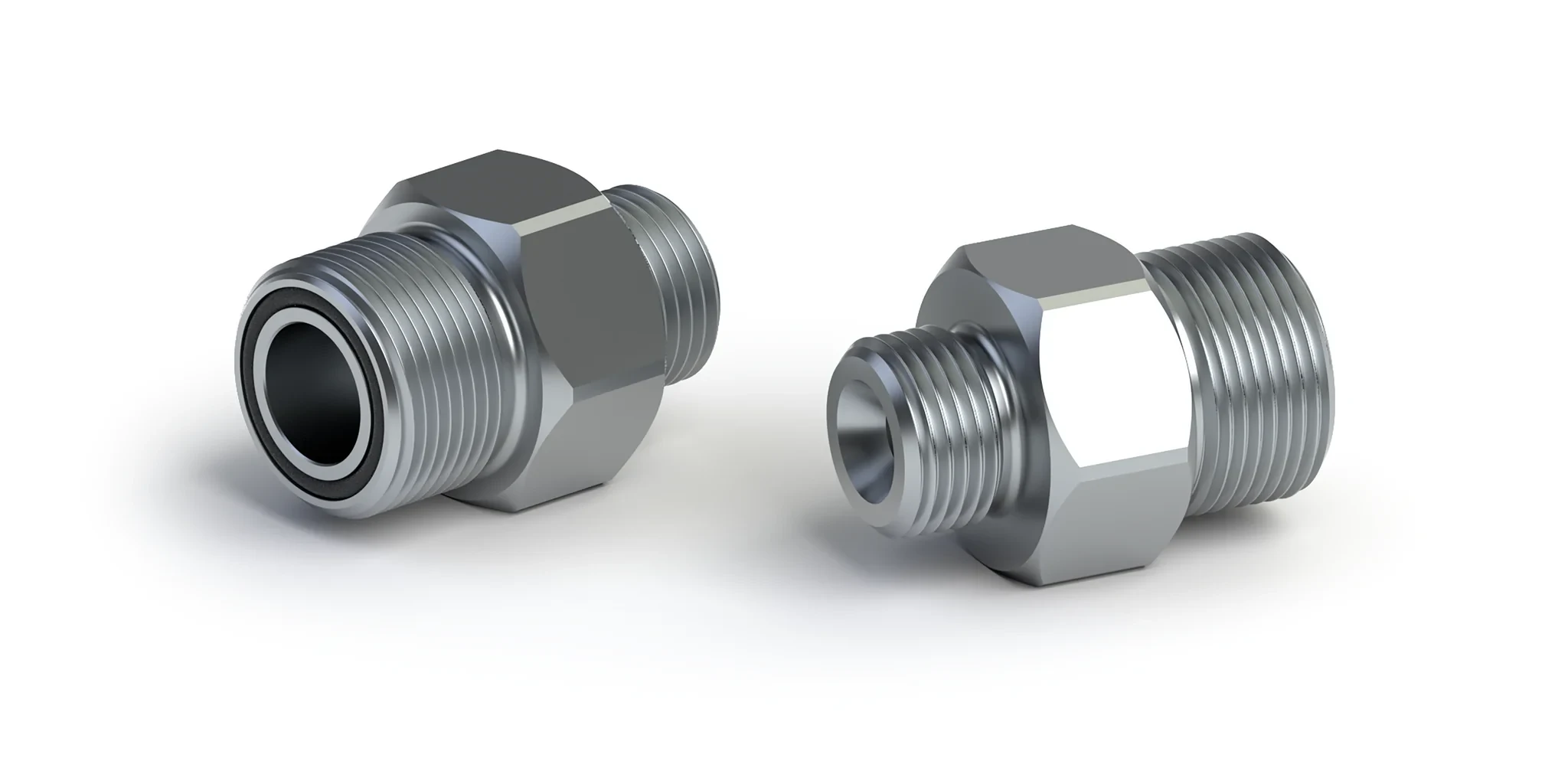

Threaded Fittings:

Threaded fittings are the stalwarts of the fitting world, offering a straightforward approach to connecting hoses by means of threads. They are versatile, available in myriad sizes and thread patterns, and are relatively simple to install.

Flange Fittings:

When the pressure rises, flange fittings rise to the occasion. These are the go-to for high-pressure situations, providing a robust connection by bolting two flanges together, with a gasket nestled between them to ward off leaks.

Quick-Disconnect Fittings:

In environments where time is of the essence, and hoses need to be swapped out with regularity, quick-disconnect fittings shine. They enable swift changes without the need for tools, streamlining maintenance and reducing downtime.

Selecting the Right Fittings for Your Application:

The quest for the ideal hydraulic hose fitting is guided by several critical considerations:

Material Compatibility:

The fitting’s material must be in harmony with the hydraulic fluid it will encounter. Stainless steel, brass, and carbon steel are among the common choices, each with its own set of characteristics suitable for different fluids and conditions.

Pressure Rating:

A fitting’s pressure rating is its badge of honor, indicating its ability to endure the system’s maximum pressure without succumbing to failure.

Size and Thread Type:

The fitting must be a match in both size to the hose’s inner diameter and thread type to the components it will connect, ensuring a seamless and secure union.

Configuration:

The spatial dynamics of the system must be considered, ensuring that the fitting’s orientation and shape do not place undue stress on the hose or impede the system’s function.

The Role of Quality in Hydraulic Hose Fittings:

Quality is the cornerstone of hydraulic hose fittings. Subpar fittings are a recipe for disaster, potentially leading to system failures, costly downtime, and safety hazards. It is imperative to source fittings from manufacturers that are committed to industry standards and rigorous quality control protocols.

China’s Role in the Hydraulic Hose Fitting Market:

China has emerged as a powerhouse in the hydraulic hose fitting industry, home to factories that churn out a vast array of fittings, including specialized ones like air brake hose fittings and swaged hose fittings. The China best swaged hose fitting factory, for example, has gained recognition for producing top-tier products that meet and exceed international standards.

Innovations in Hose Fitting Technology:

The hydraulic hose fitting industry is in a constant state of evolution, with manufacturers on a quest to enhance the functionality and user-friendliness of their offerings. Innovations such as no-skive technology, which does away with the need for hose skiving, are simplifying the installation process and bolstering reliability.

Cam and Groove Couplings:

Cam and groove couplings, affectionately known as camlock fittings, have carved out a niche for themselves in the world of quick and tool-free hose connections. Their versatility has made them a staple in a diverse array of applications, from transferring water to handling chemicals.

Exploring Different Cam and Groove Fittings:

Cam and groove fittings come in various styles to suit different needs:

This size strikes a balance between adequate flow rate and manageability, making it a popular choice for medium-sized applications.

Banjo Cam and Groove:

Banjo fittings are the solution when space is at a premium, offering a low-profile connection that is particularly useful in agricultural and chemical settings.

Conclusion:

Wholesale hydraulic hose fittings are the unsung heroes of hydraulic systems, ensuring the integrity and efficiency of operations across a multitude of industries. Armed with the knowledge of fitting types, applications, and the criticality of quality, you can navigate the market with confidence. Whether you’re in search of China air brake hose fittings or considering the advantages of cam and groove couplings, selecting a trustworthy supplier is key to securing the right fittings for your unique requirements. With the right expertise and resources, the longevity and performance of your hydraulic systems are assured.